The upcoming construction picture for a Temiskaming-area cobalt refinery is beginning to take shape with the awarding of a major metals processing contract.

First Cobalt selected Metso Outotec for the design and manufacturing of the equipment for a new solvent extraction plant and its process controls. Metso Outotec is a leading global company in the field of sustainable mineral processing and metal refining equipment.

According to a First Cobalt news release, Metso Outotec was selected from a tendering process based on its s"competitive pricing and a technical superior bid."

The company has provided similar equipment to other cobalt sulfate refineries around the world.

First Cobalt did not provide any details on the value of the contract in an Oct. 5 news release nor set a date for the start of construction at the site.

The former Yukon refinery, located just outside the town of Cobalt, was acquired by First Cobalt in 2017. Built in 1996, it was placed in mothballs by the previous owners in 2015.

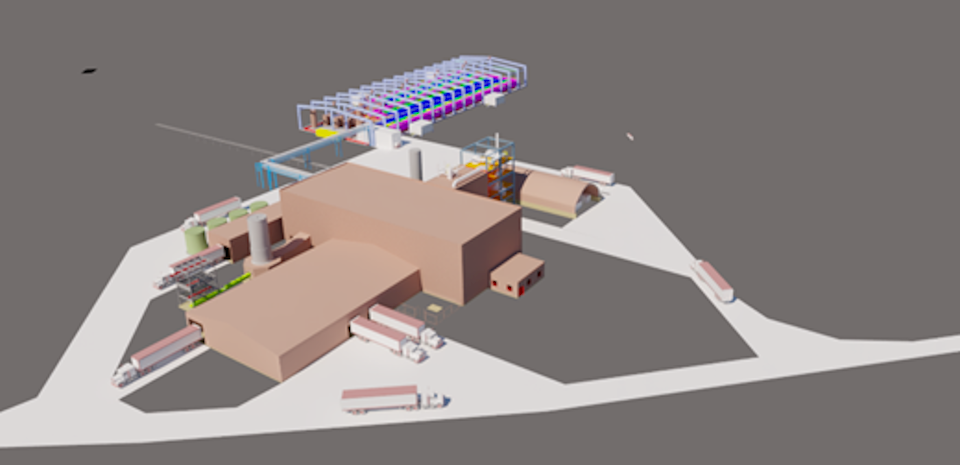

First Cobalt has already spent $100 million on plant upgrades with new equipment, an access road and on power infrastructure. The Toronto-based metals processor intends to spend $60 million more to graft a new addition onto the existing refinery building, which will roughly double its size.

The company's timetable is to commission the refinery by the fourth quarter of 2022, targetting annual production of 25,000 tonnes of cobalt sulfate.

The plan is to process unrefined cobalt hydroxide, coming from Africa, into cobalt sulfate, which is used in the electric vehicle (EV) market.

First Cobalt has secured long-term supply deals with Glencore AG and IXM SA, a subsidiary of CMOC of China to ship in unprocessed cobalt from the Democratic Republic of Congo to northeastern Ontario in late 2022.

Once operational, the refinery will be North America's only producer of battery-grade cobalt for the EV market. About 80 per cent of the world's processed cobalt currently comes out of China.

First Cobalt said negotiations with automakers and battery suppliers are ongoing.

Beyond processing cobalt, the company is studying the possibility of expanding operations in Temiskaming by also handling nickel and extracting recovering valuable critical metals from spent batteries

In a statement, First Cobalt president-CEO Trent Mell was pleased with the selection of Metso Outotec.

"Their expertise and ability to deliver quality projects significantly de-risks our own. We move one step closer to becoming North America’s only provider of cobalt sulfate and we do not intend to stop there. Plans for our Canadian Battery Materials Park also include battery recycling, nickel sulfate production and a partnership with a battery precursor manufacturer.”